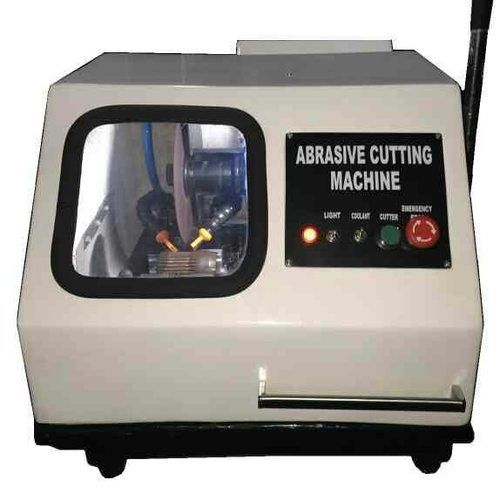

Abrasive Cutting Machine

Product Details:

Abrasive Cutting Machine Price And Quantity

- 1 Piece

- 75000 INR/Piece

Abrasive Cutting Machine Trade Information

- Cheque

- Australia North America South America Eastern Europe Western Europe Middle East Central America Africa Asia

- All India

Product Description

Abrasive cutter is rugged, sturdy and designed to cut Metallurgical Samples to optimal quality consistently and safely . Cutting Wheel spindle is connected with motor shaft by pulley and belt mechanism. The movement of cutting wheel towards the specimen is applied by handle fixed with motor base pivot spindle and the cutter unit is balanced by springs for smooth chop type movement. Corrosion resistant window. Cooling by two high flow water jets to provide optimum cooling. Large (25mm) drain, re-circulation coolant tank with 30LTR. Capacity Working on 440 volts, AC main supply with coolant tank of sufficient capacity. The chop type cut off wheel machine is suitable for quick and clean cutting of metallography specimen from rods & tubes etc.

Features-

X-Y Movement Vice is made up of M.S, Specially designed.

Coolant circulation System is provided with suitable filtering arrangement.

Light attachments system is provided for clean and accurate cutting of samples.

Heavy Duty motor is provided 3 H.P , 3 Phase.

Large Viewing window to monitor the cutting operation.

Technical Data-

Operation -Manually by moving motor to cut the sample.

Cutting Operation :- By manual cutt-off wheel in chop type procedure.

Cutting Motor Power :- 3H.P,3 Phase.

Coolant Motor Power :- Tullu Pump.

Cutt-Off Wheel Speed :- 1400 RPM.

Dimensions :- 600mm W x 750mm D x 1000mm H. (Approx.).

Cutting Capacity :- 10-60mm.