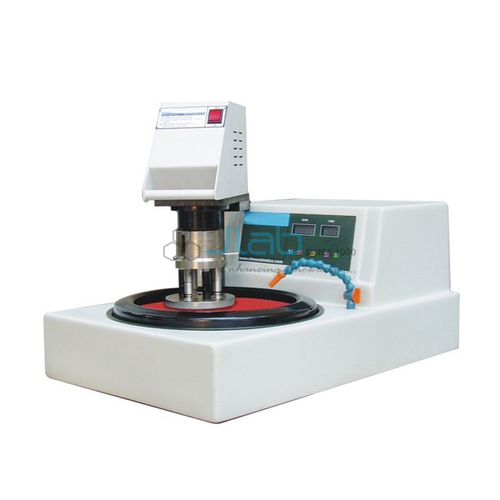

Automatic Polishing Machine Single Disc

175000 INR/Piece

Product Details:

- Max Height Approx. 300 mm

- Number of Specimens Up to 6 (with holders)

- Mounting Type Bench top

- Hardness Hardened steel and composite for durability

- Temperature 5C to 40C

- Accuracy High precision finish, repeatable results

- Frequency 50Hz

- Click to view more

X

Automatic Polishing Machine Single Disc Price And Quantity

- 175000 INR/Piece

- 1 Piece

- Polishing cloth, water inlet, drain pipe, abrasive dispenser

- CE certified

- 450 x 410 x 370 mm (LxWxH)

- Aluminium alloy with protective coating

- Powder coated steel cabinet

- Yes

- Special non-corrosive metals

- 0-60 min, programmable

- 0.5 HP

- < 70 dB

- Continuous water flow

Automatic Polishing Machine Single Disc Product Specifications

- Single Disc

- Approx. 300 mm

- Bench top

- Hardened steel and composite for durability

- 203 mm (8 Inch) Disc Diameter

- Automatic

- Up to 6 (with holders)

- 5C to 40C

- Laboratory, Research, and Industrial

- Metallographic sample polishing

- Fine agitation/resolution of abrasive movement

- 85% RH

- High precision finish, repeatable results

- 50Hz

- Automatic Polishing Machine Single Disc

- Up to 30 mm diameter

- Automatic

- Digital

- Instantaneous start/stop

- 50 to 500 RPM (Variable)

- Touch Panel/Buttons

- 220V AC

- Approx. 50 kg

- 220V AC, 50Hz

- Variable speed, timer, stable operation, anti-vibration enclosure

- Adjustable

- Standard Mains

- Suitable for a wide range of metallographic samples

- Polishing cloth, water inlet, drain pipe, abrasive dispenser

- CE certified

- 450 x 410 x 370 mm (LxWxH)

- Aluminium alloy with protective coating

- Powder coated steel cabinet

- Yes

- Special non-corrosive metals

- 0-60 min, programmable

- 0.5 HP

- < 70 dB

- Continuous water flow

Automatic Polishing Machine Single Disc Trade Information

- Asia, South America, Western Europe, Middle East, Africa, Central America, Australia, Eastern Europe, North America

- All India

Product Description

We have gained a remarkable position in theindustry by offering a qualitative assortment of Semi-AutomaticPolishing Machine Singe Disc. Thesepolishing machines are accessible in numerous specifications as per thevariegated demand of customers. The offered polishing machines are developedusing optimum quality material and sophisticated technology keeping in syncwith standards of market. Additionally, we offer these polishing machines afterexamine them properly on numerous parameters.

Features:

- Reliable performance

- Accurate results

- Durability

Specifications:

- Grinding and Polishing Wheel Diameter: 250mm

- Abrasive Paper Diameter: 250mm

- Platen Speed: 100-1000rpm

- Operating conditions 10 to 40°C

- Electronic control with LC-Display with digital timer/Touch Screen

- Independent polishing head motor

- 1 HP High torque AC motor

- 10Aluminum Disc hold up to 3 moulds(30/45mm)

- Variable Speed 50-600 RPM

- Specimen Preparing Time 0-99Min.

Advanced Performance and Control

Equipped with an automatic control mode, variable speed adjustment, and a digital touch panel, this single disc polishing machine offers comprehensive control for precision sample preparation. The programmable timer (up to 60 minutes) and instantaneous start/stop response ensure workflow efficiency and consistent outcomes. Whether in a research institute or industrial lab, operators benefit from high accuracy and stable performance.

Durability and Safety Features

Constructed from a mix of aluminium alloy and specially selected, non-corrosive metals, the polishing disc and plate stand up to rigorous, repeated use. The powder-coated steel enclosure is complemented by a safety interlock system and anti-vibration structure, minimizing operational hazards and maintenance needs. The machine operates quietly (noise level below 70 dB), making it well-suited to busy laboratory environments.

Optimal Cooling and Sample Versatility

A continuous water flow cooling system ensures samples remain at safe temperatures, even during extended polishing cycles. The machine accommodates up to six specimens at a time, each with a diameter up to 30 mm, catering to a wide range of metallographic sample types and research requirements. Standard accessories include polishing cloth, abrasive dispenser, and connections for water inlet and drainage, streamlining the setup process.

FAQ's of Automatic Polishing Machine Single Disc:

Q: How does the automatic polishing machine achieve a high-precision finish?

A: The machine utilizes a variable-speed aluminium alloy disc with a special non-corrosive metal polishing plate, delivering fine abrasive agitation and precise control through digital touch panel or buttons. This, combined with programmable timing and stable, anti-vibration operation, ensures repeatable, high-quality polishing results on metallographic samples.Q: What types of samples and specimen sizes can be processed with this machine?

A: It is designed to handle a wide variety of metallographic samples, accommodating up to six specimens simultaneously, each with a maximum diameter of 30 mm. This versatility makes it suitable for laboratory, research, and industrial applications.Q: When should the programmable timer be used, and what is its range?

A: The programmable timer, with a range of 0-60 minutes, should be set according to the specific requirements of the sample being polished. It allows users to precisely control the duration of the polishing cycle, enhancing consistency and outcome quality.Q: Where is the machine best installed for optimal performance and safety?

A: The machine is designed for benchtop mounting in controlled laboratory, research, or industrial environments. Ensure the area has access to a standard mains power supply (220V AC, 50Hz), proper ventilation, and water inlet and drain connections for cooling.Q: What is the process for preparing metallographic samples using this automatic polishing machine?

A: Place the specimen holders with samples onto the disc, select the desired speed and duration, and start the polishing cycle using the touch panel or buttons. The machine's automatic operation, in conjunction with continuous water cooling and an abrasive dispenser, ensures efficient and precise sample preparation.Q: How does the cooling system benefit sample quality during polishing?

A: The continuous water flow cooling system prevents samples from overheating during extended cycles, which reduces thermal damage and preserves specimen integrity, crucial for achieving accurate metallographic analysis.Q: What are the main benefits of using this automatic single disc polishing machine?

A: Key benefits include high-precision and repeatable results, user-friendly automatic controls, reliable safety features, quiet operation, robust construction, and compatibility with multiple sample sizes and types, making it ideal for demanding laboratory and industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email